Ivoprop - Ivo prop - Ivo propeller

1-800-FOR-PROP

Ivoprop service bulletins

Subject:

Ivoprop ultralight & model 3:1 gearboxes or direct drive engines or 3

cylinder engines. Note This Service Bulletin supersedes any previous

operational alerts issued by Ivoprop Corp.

Purpose:

To detect blade

movement inside the hub due to improper installation and, or harmonic resonance

between prop and power plant; To prevent further flight if this situation

is detected and develops in unsafe condition (aluminium bushings becoming

loose breaking bolts, blades etc ... ) "new blades do not have

bushings"

Introduction:

Above mentioned

combinations produce high level of torsional pulses during their firing

cycle which several times exceed their nominal torque and also torque

reversal pulses. If the prop is mounted loose and or gets in harmonic

resonance with the engine the blades could move inside the hub back and

forth in a plane of prop rotation.

What

to do: Prior to the

next flight, accomplish the following:

Get

torque wrench and check its calibration by hanging a known weight on its

arm and multiplying the weight in pounds by arm in inches. This reading

should be as close as possible to actual recommended torque on mounting

bolts. (We tried several torque wrenches and most of them were off by a

lot.) Check torque on mounting bolts. 200 inch x lbs.

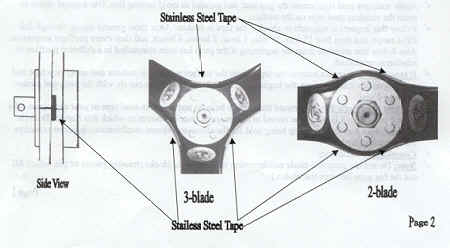

Direct

drive engines only: Mark the prop position in relation to the

crankshaft. There are two positions to mount 3-blade prop and three

positions to mount 2-blade prop; this makes a great difference in how

the

prop and engine vibrate together and each position creates a totally new

situation. It is impossible to determine which position is best for your

particular prop engine airframe combination without actually testing it on

it.

Run

the engine momentarily on the ground trough the full RPM range.

Check

the torque on the mounting bolts and, if you are not using locknuts, safety wire

the bolts.

Cut the strips of stainless steel tape about 2" long and

'/4" wide (tape supplied with this service bulletin) Clean the area

around the gap between blades, or gap between blades and blade blocks with

MEK solvent.

Apply

stainless steel tape across the gap next and parallel to mold parting

line. Use a round object to press the stainless steel tape on the surface.

Follow this inspection schedule to check if the tape is broken:

After short ground run up through full RPM range, and then first 15 min,

30 min, I hour, 2 hours, 4 hours, and then every preflight inspection.

Also follow this schedule from the beginning if the prop has been

reinstalled in a different position in relation to crankshaft.

If

tape breaks or

cracks remove the tape, clean the surface with MEK solvent and apply new

tape and start inspection schedule from the beginning. If tape breaks

again, do not fly with the prop and contact Ivoprop Corp.

Request

to dealers: Please forward

this service bulletin and stainless steel tape to your customers who are

subject to this S.B. Keep the record of addresses of your customers to

which this Service Bulletin applies. Make sure that any prop being sold

for the above-mentioned combinations is accompanied by this Service

Bulletin.

Compliance:

Mandatory

Note:

Do not use prop in 2-blade configuration without blade blocks

(missing

pieces of pie, which fill out the big gaps between the blades.)

Ways your prop can come loose!

Not

torquing the bolts

Do not rely on feel. Get torque wrench and calibrate it by yourself.

Torque on mounting bolts is 200 inch x lbs. ( not 200 ft x lbs.)

Bottoming

the thread of the mounting bolts into the flange or lock nuts. Use

extra washers if the bolts are too long.

Inserting

spinner composite baking plate anywhere between what bolts is supposed

to compress together.

These fiberglass or composite backing plates compress with heat and

pressure resulting in torque loss on the bolts.

Using

wrong hardware.

Rotax engines are supplied with prop crush plate which has stamped

oversized holes. Do not use it.

Important

:

Do

not modify the prop in any way.

Do

not weld super cams on torsional rod.

Direct drive engine adaptors need AN5 bolts not 8mm bolts.

Knurled Plates Instructions - Ultralight Model

The knurled

plates should be installed so that knurling finish on each plate is in

contact, with blades.

The knurled

pattern is 60 degrees symmetrical so, if you re-install the blades between

crush plates later in a different position, the imprint on the blades

should match the knurled pattern. However, due to manufacturing

tolerances, to get the best match, number the blades and plates and always

put the blades back in the same place.

Torque the

mounting bolts to 200 inch x lbs. Dry (no oil or

lubricant the thread) and run the prop momentarily through full RPM range.

Re-torque the bolts.

Install the

Service Bulletin stainless steel tape and follow the inspection schedule

from the Service Bulletin. Any time you inspect the tape, check the torque

on the bolts during first four hours. After that, check torque every ten

hours.

If your blades have aluminum bushings around the bolt holes, make sure that knurled plates supplied to you are counter bored around the bolt holes.

If you require further information email us at:ivoprop@gmail.com

IVOPROP

CORP

2615 East 67th St. Unit E

Long Beach, CA 90805

562-602-1451

ivoprop@gmail.com

1-800-FOR-PROP