HOW IT ALL STARTED

3 A.M., August 4, 1984

Prague Czech Republic.

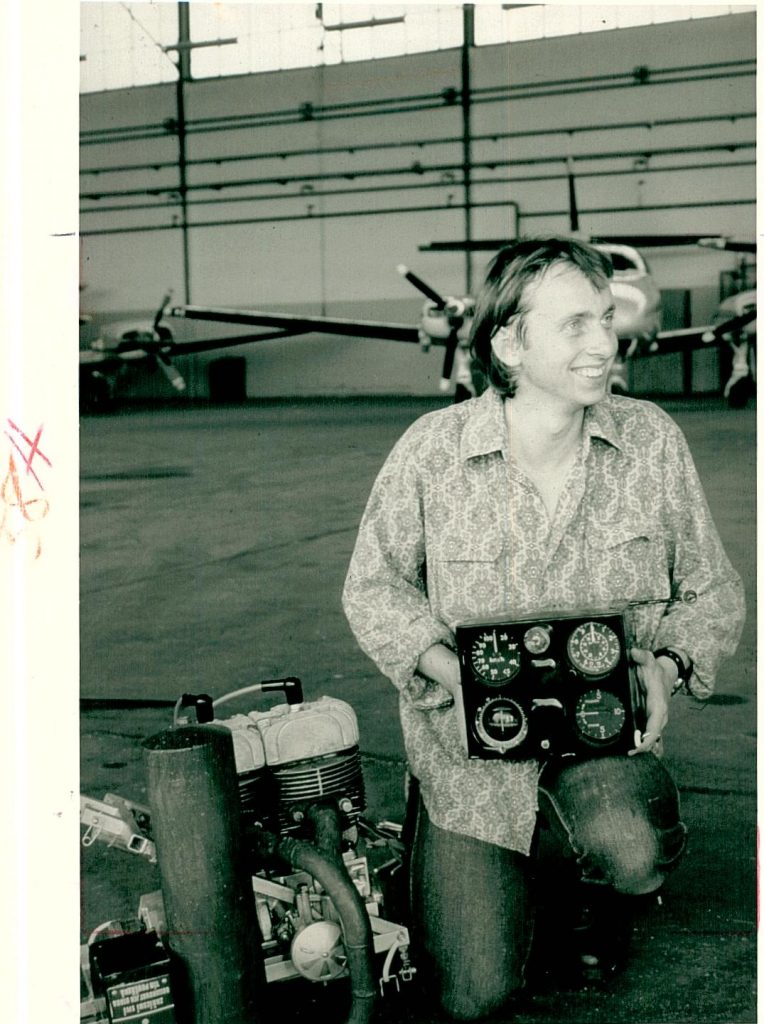

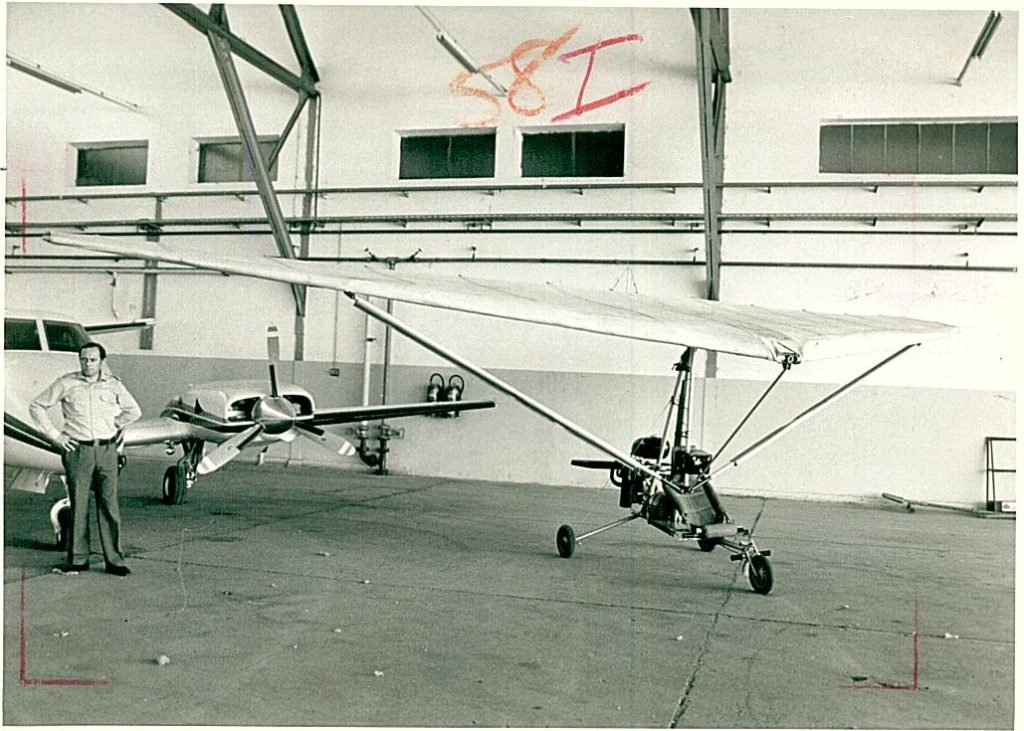

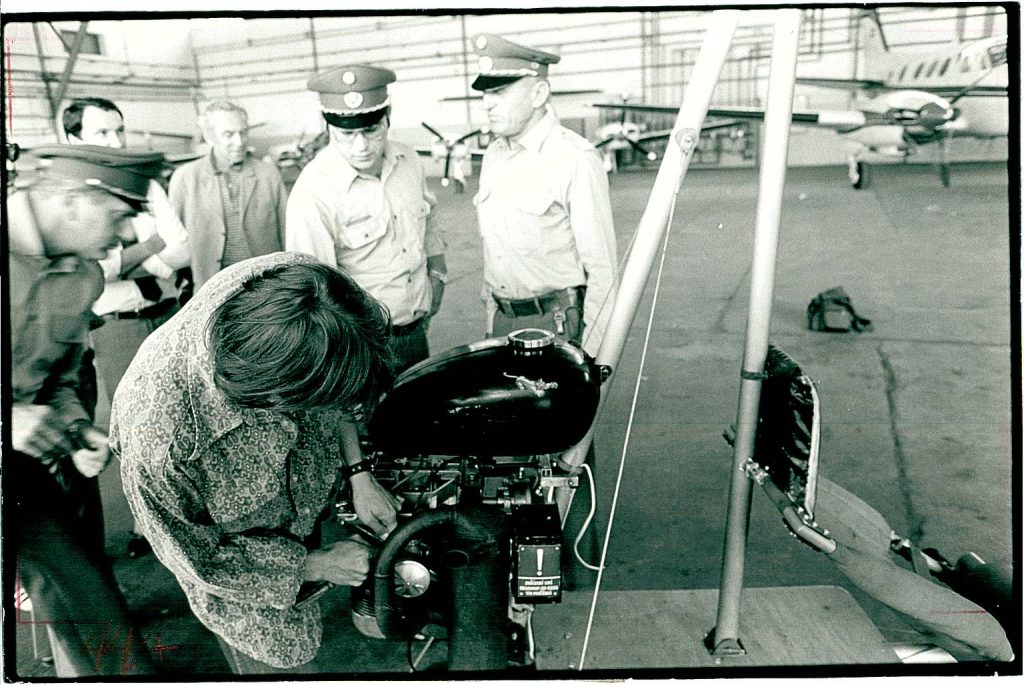

A young man, working in starlit darkness, feverishly completes the assembly of a homemade trike aircraft. Carefully, he points the wheels in the direction of Vienna, thirty miles away on the other side of the Czechoslovakian border The silence is finally broken by the starting of a two-cylinder Trabant auto engine and the quiet swishing of the propeller sound swells to a blare as the shadowy delta-wing moves forward across the plowed field and lifts off. Ivo Zdarsky is on his way to becoming the first refugee to successfully fly a homebuilt aircraft over the Iron Curtain to freedom.

Ivo has sold over 20,000 propellers since making the one that carried him out of Communist Czechoslovakia. He sold that one along with the rest of his trike to a West Berlin museum that features escape vehicles. If you go to Berlin and see Ivo’s trike on display, notice the nick in one of the (fiberglass?) prop blades. As he took off, he heard a rock hit one of the blades. Had he made the prop from wood, he says it probably would have broken. Instead, it held together as he flew above the trees toward a border radar station. Directly above the station, he pushed the engine to full power and climbed inside the radar’s cone-shaped blind-spot to a couple of thousand feet, then glided swiftly across the Danube River to safety in Austrian airspace.

Perhaps the sound of that rock hitting his prop is one reason Ivo’s propellers are all made with stainless steel leading edge Their carbon-graphite composite construction is extremely strong, as evidenced by a piece of twisted exhaust pipe that matches the dent in an unbroken blade that was on display at Sun-N-Fun this past April. Another indication of Ivoprop’s strength is the amount of resilient flex visible when the props under load. They are actually designed to bend and twist for maximum efficiency in flight. Ivo’s genius and craftsmanship not only carried him safely out of Communist Eastern Europe but soon made him one of the world’s leading manufacturers of aircraft propellers.

Ivo (he prefers to be known by just his first name) modestly, tells how he began making propellers in his country. After being shuttled around Austria for six weeks to hide from the Czech version of the KGB, he was flown to California to begin new life. Since he had started with a trike that he built secretly in Prague and had taught himself to fly, he began to build another in the U.S. by first making a propeller. He sold the prop at an airshow for enough profit to build two. Those provided enough money to make four and so on. Now almost 3,000 Ivoprops are built per year. They are widely used in Europe and have been certified in England by the C.A.A. One is even on its way to Mars as the first interplanetary Ivoprop – it will be used to propel an airborne exploration vehicle in the harsh Martian atmosphere.

The secret of Ivo’s success is a combination of low price and unique features. Most notable is a simple pitch adjustment using a torsional rod embedded in each blade, which can be twisted by a cam in the propeller hub. Turning a screw adjuster in the center of the hub simultaneously sets the pitch of all blades without having to use protractors or torque wrenches to retighten hub bolts. The ground adjustable “Ultralight” model for two-stroke engines of up to 100 horsepower weighs only six pounds with two blades and hub ($340) or eight pounds for three blades ($460). Like the Magnum model for engines up to 700 horsepower, as many as six blades can be used on a single hub.

Both models are also available with electric motors, which can turn the screw adjuster in flight. Ivo says in-flight pitch adjustment is like shifting the gears of a car in order to save fuel, engine wear and reduce noise. The pilot uses a switch in the cockpit similar to operating automobile electric windows and observes the results on the engine RPM meter. The in-flight adjustable ultralight model weighs 1.5 pounds more and costs another $400. This torsional twist system was originally developed by Ivo on his own ultralight trike.

An interesting possibility with these interchangeable blades is that one can remove one or more blades, reassemble the propeller and fly away with just two blades. Ivo has occasionally flown his trike to the top of desert buttes to spend a night alone in free solitude (he also likes to fly his helicopter to remote places). He has had reason to appreciate the versatility of his propellers when making hard landings on rocky surfaces surrounded by sheer cliffs. A damaged blade does not necessarily mean the aircraft is grounded in some inaccessible spot.

In response to questions about the reliability of Ivoprops, Ivo states that the company stands behind all of its products. Even competitors acknowledge Ivo’s integrity and fairness in replacing parts and paying for damage in some early incidents that very likely were not his responsibility. Incorrect torque of hub bolts results in vibrational wear around bolt-holes and cracks near the hub-end of blades. When neglected, this can lead to complete failure of the blade.

A service advisory was sent out years ago detailing the sequence necessary to torque the bolts (install, run, re-torque and check after the first 15 minute flight). Knurling (i.e.. teeth, like on the surface of a metal-file) was added to the crush plate that sits against the base of the blades and the blades themselves were strengthened. Metal tape is now used across the joint between blades so that any relative movement can be easily seen during preflight inspections.

Ivo smiles wryly as he explains how some genius in Austria designed a precisely 3:1 gearbox reduction drive for propellers. Some two-stroke engines mounting three-blade props are thereby timed to fire with the blades at exactly the same positions in the rotational circle with each impulse. The resulting resonance compounds forces acting on the propeller blades, jerking them at the same rate as engine RPM. Friction from Improperly torqued hub bolts will wear the blade base and cause stress cracks from overheating. Installation according to Ivoprop directions with the crush plate seated correctly and hub bolts torqued to 200 inch-pounds prevents this friction.

The latest Ivoprop development is a powered-parachute application using a tandem pair of two-blade propellers mounted in an X-configuration of 60/120 degrees rather than 90 degree right angles like a standard four-blade prop. The military Apache helicopter successfully uses this to produce an effect known as hyper-acceleration. Under the right conditions, the leading blade accelerates air into the following blade the way multiple turbines in jet engines increase airflow to achieve more thrust. As much as 430 pounds static thrust with a Rotax 582 engine have been measured using the X-prop, though this varies with changes in pitch and density altitude.

Despite all of the attention and fierce competition Ivo has endured throughout the years since he flew over the Iron Curtain in his home-made trike, he remains the same quiet young man as then. Even though more Ivoprops have been sold than any other type, he is still an unassuming free-spirit who refuses to be molded into the image of a professional businessman. Instead, he seems reluctant to even talk about himself or his company.

Occasionally while talking, he looks away as though yearning to be alone in the sky soaring toward some invisible infinity. But he becomes inspired when describing some solitary desert flight or that lonely night of August 4, 1984,

“… I wanted to leave (Czechoslovakia) at 3 a.m. because that is when people were least active. So I ended up flying over Vienna for two hours like a tourist then went looking for the international airport. I circled the tower twice but there was nobody in the tower! Ha ha! It was still dark then – this is the fun part – I saw a 747 being towed along a taxiway. There was a little bit of light there, so I landed beneath the wing of this Boeing. Enough room for two trikes! Besides, mine didn’t have a pole or wires on top but was strut-braced.. something from having to keep a low profile when flying below electric lines. Anyway, a mechanic came running out, yelling. I raised my hands with an expired Czech passport and asked for political asylum. Then they were really nice to me …. “

Ivo Zdarsky

The name of this untamed Bohemian means more than just another airplane propeller.

Ivo represents the freedom of flight – as well as a practical way to get there.

By Jim Bethea Ultraflight Magazine